What is the price of setting up a biscuit or baked products production line with enough output to sell to supermarkets and retailers?

If you love baking and have a keen interest in the food processing sector, then it is one of the best businesses for you. Also, it is a financially lucrative venture. Basically, biscuit manufacturing comes under the conventional bakery industry.

When opening a biscuit and cookie manufacturing factory on a medium or large scale, then you will require better planning. From picking the recipe to identifying your clients, all must be done during initial days.

This article includes a detailed biscuit making sample project profile with cost, machinery, production process and raw materials. Also, it contains financial analysis with the business license and permissions you need to start a small-scale unit.

8 STEPS TO START A PROFITABLE BISCUIT MAKING BUSINESS

STEP 1:Analyze themarket opportunity for biscuit making

The biscuit market is very promising and expecting a higher growth in the near future. Biscuit market is all about effective decision-making, and strategic planning as to how to sell, what kind of packaging should be done, what will be the pricing strategy etc.

Generally, the success of a biscuit brand depends on several factors including innovative packaging, new flavors, tastes, shapes etc. Also, rising health consciousness among consumers through the electronics media is effective in the Indian consumer market. Simply, offer as many as variety you can at a cheaper price than an established brand.

STEP 2: Determine your product

After analyzing your local market, determine your product that you are going to produce. It’s very important. Biscuits are easy to carry, tasty to eat, cholesterol free and reasonably priced. Actually, different types of biscuits you can find in the market. Some of the most popular are thin arrowroot, sugar-free, wafer, salted, cream biscuit, coconut biscuit, ginger biscuit, jeera crunch, digestive etc.

Hence, you will need to determine what specific type of biscuit you want to produce. Also, you need to fix the shape, taste, and flavor. Because you have to procure the mold according to the shape. Also, you have to craft the specific recipe as per the taste and flavor you want to provide.

STEP 3:Selection of the area

For setting up a small or medium manufacturing factory, you will need sufficient area. Place is necessary for storing raw ingredients, utensils, and keeping the commercial level machines. Rent a place that has enough room to hold all machines, and has space to spare.especially the room length is important for automatic biscuit production line,too short is not enough to set up the machine.we suggest 17meters length minimum.rent one 120 to 200 square meter room.

STEP 4:Attain necessary permits

After settling the issue of space, you need to get in touch with respective authority to get the clearance and permits. These are necessary to run business legally. Manufacture process can only start when the food and health department offers their seal of approval.

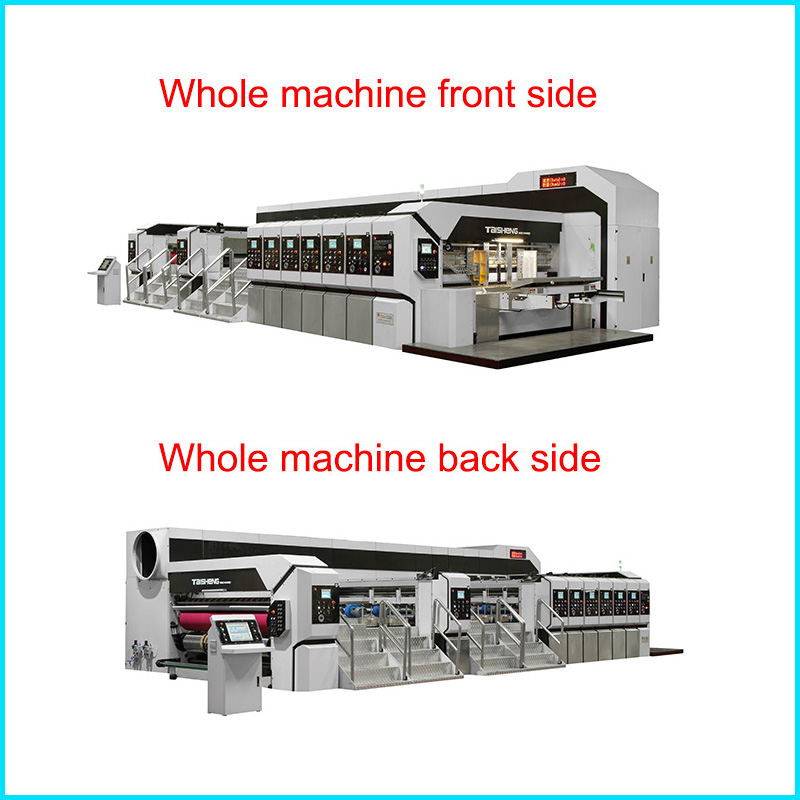

STEP 5:Get necessary machines

To manufacture biscuit on a commercial level, you will need commercial grade machines. Any automatic biscuit manufacturing machine costs anything between 10000 dollars to 20000 dollars. All you need is to pour in ingredients according to measurements. The mixing, kneading, cutting and baking will be done by this one machine.

STEP 6:Attainment of ingredients

The list of raw materials will vary according to the selected recipe. As the commercial machines produce bigger batches, one will need these raw materials in proportional amounts. It is best to get in touch with whole sale suppliers of these materials.we provide biscuit formula and technical service as well.

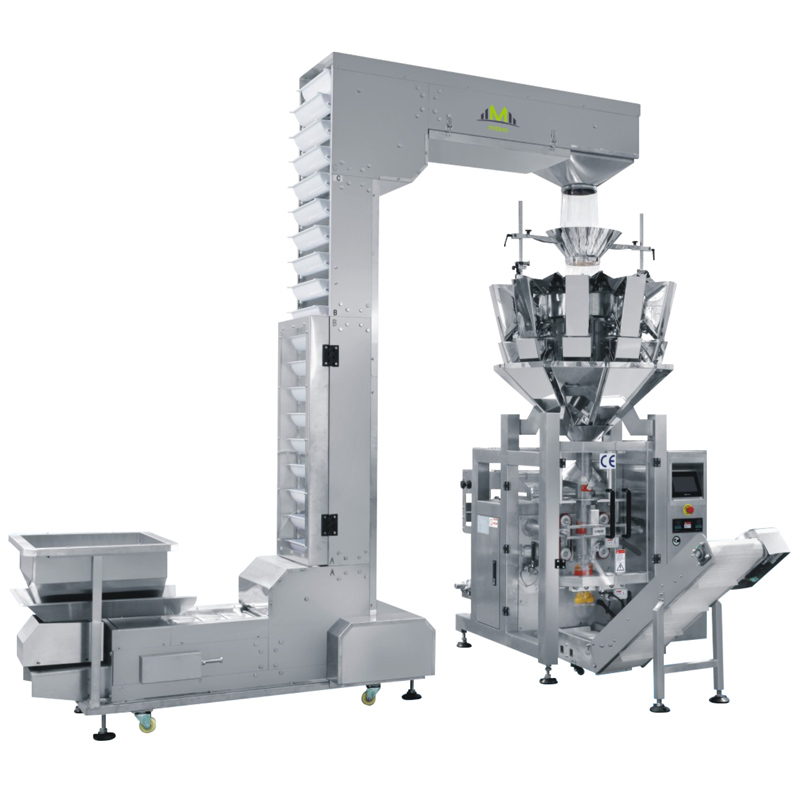

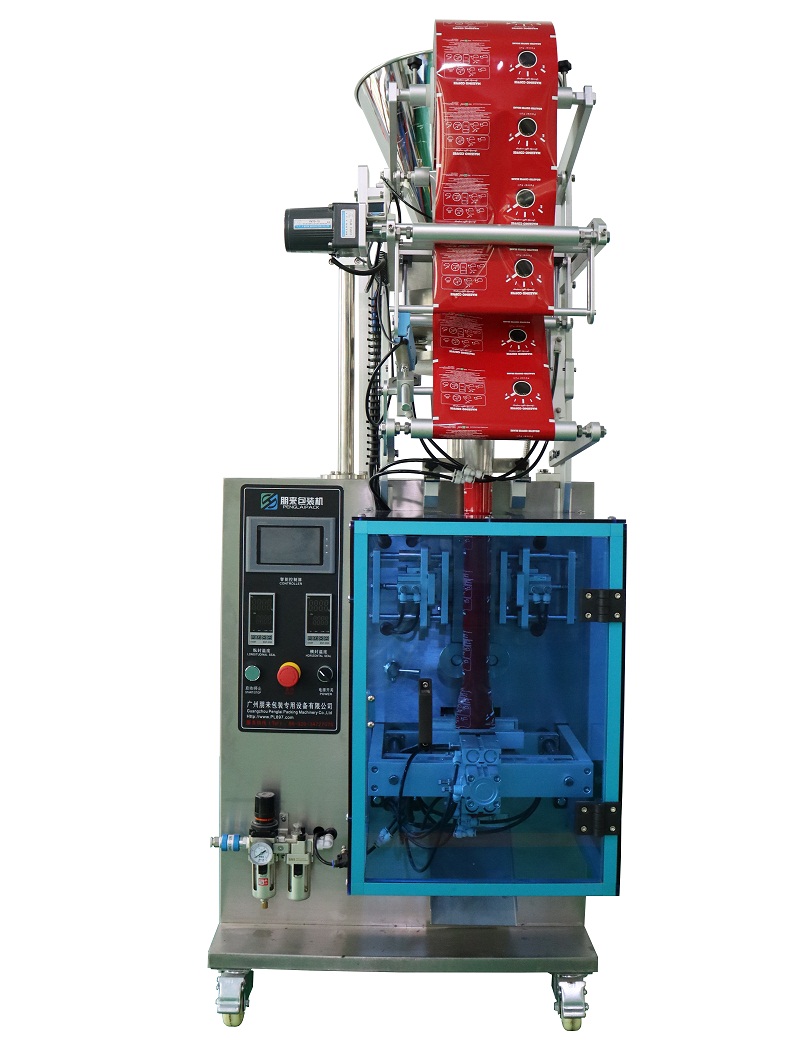

STEP 7:Packaging the biscuits

In commercial units, biscuit packaging is also done by machines. It is not possible for people to collect, place and pack so many biscuits manually. Multi-row biscuit packing machines are also available online. The cost of these machines starts from 5000 dollars.

STEP 8:Selling the product

Once the biscuits and cookies have been packed, it is time to transport these to selling counters.

Angelon Supports the Black Pepper Processors by Providing Optimized Sorting Performance

Angelon Supports the Black Pepper Processors by Providing Optimized Sorting Performance